01

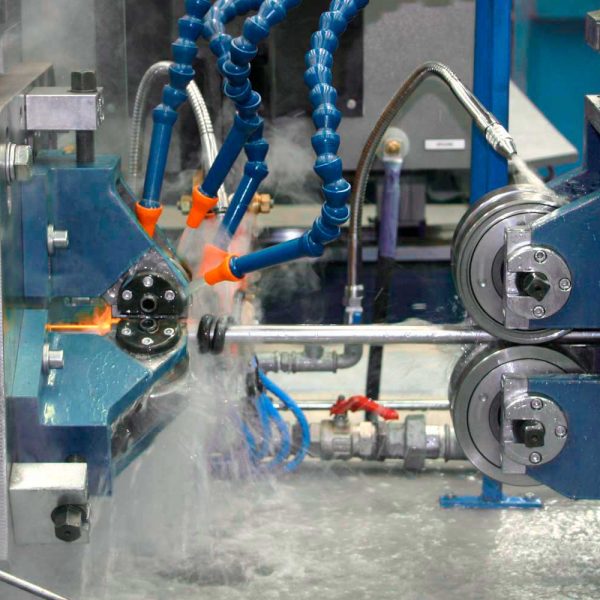

Welded Tube lines - ERW

Complete lines:

Our production Lines cover a very wide range for the manufacture of welded tubes (ERW) with ranges from Ø 12,7 mm up to Ø 300 mm and thicknesses from 0.6 mm up to 12,7 mm.

Bonak adjusts to the needs of each customer to either customise or apply standards to help the customer achieve the right installation.

As the market for Welded Tubes is very extensive, each model of Welded Tube Line covers a specific range of diameters and thicknesses.

| Line Code | Diam. range(mm) | Derivate Square / Rectangular range(mm) | Thickness range (mm) | Max. Speed range (m/min) | |

| BKT-1 | 160-1025-LT | 10-32 | 10×10 – 25×25 | 0,6 – 1,5 | 100-160 |

| BKT-2 | 160-1250-LT | 12-50 | 10×10 – 40×40 | 0,8 – 2,0 | 100-160 |

| BKT-3 | 140-2076-LT | 20-76 | 16×16 – 60×60 | 0,8 – 3,0 | 80-140 |

| BKT-4 | 130-25100-LT | 25-100 | 20×20 – 80×80 | 1,0 – 4,0 | 60-130 |

| BKT-5 | 120-32127-LT | 32-127 | 25×25 – 100×100 | 1,2 – 5,0 | 40-120 |

| BKT-6 | 90-50152-LT | 50-152 | 40×40 – 120×120 | 1,5 – 6,0 | 20-90 |

| BKT-7 | 80-50178-LT | 50-178 | 40×40 – 140×140 | 2,0 – 7,0 | 10-80 |

| BKT-8 | 70-76203-LT | 76-203 | 60×60 – 150×150 | 2,5 – 8,0 | 10-70 |

| BKT-10 | 40-100250-LT | 100-250 | 80×80 – 200×200 | 3,0 – 10,0 | 10-40 |

| BKT-12 | 40-127300-LT | 127-300 | 100×100 – 225×225 | 6,0-12,7 | 10-40 |

The above chart will help our customers to obtain the standard ranges of WTLs.

02

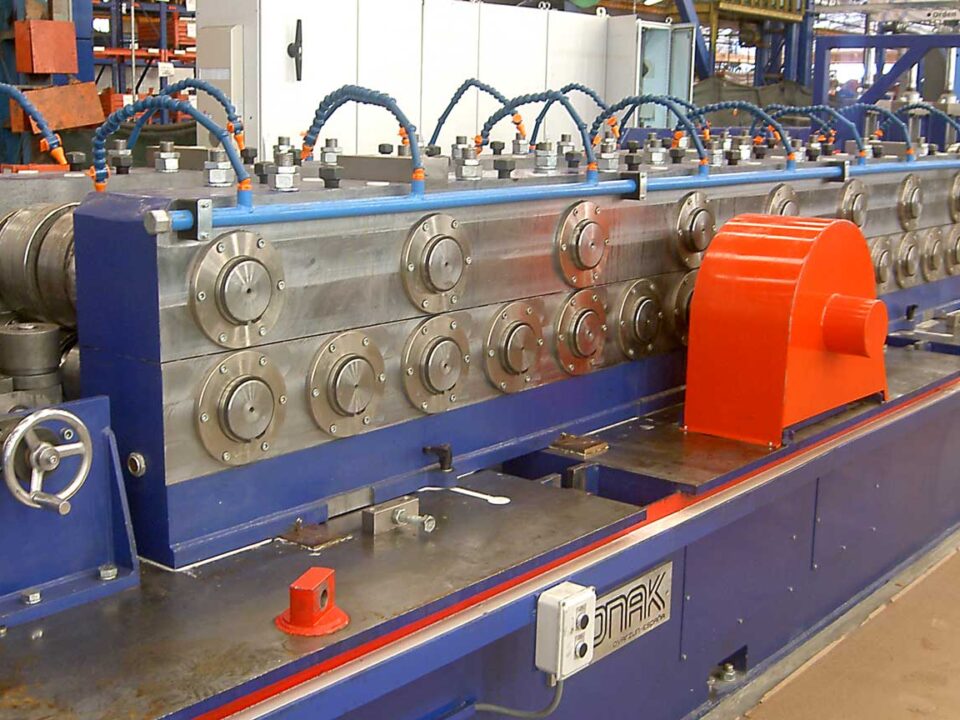

Straight to Square / Rectangular Tube lines

Maximum flexibility and productivity

Using high levels of automation with electronic control of the stands for automated opening and closing, Bonak’s HSU (TDCR for its acronym is Spanish) lines offer a high-speed tube mills for tubes from 20 x 20 mm to 150 x 150 mm, and yet with precise control of the radius.

One of the main features of this type of line (HSU) is the possibility to quickly change tube sizes without changing the rollers, which enables maximum flexibility and productivity for the customer.

This new system saves between 3-4% on the cost of strapping required for each size of tube, which in turn is extremely interesting.

Very precise control of radii.

It is important to be able to produce small production batches very quickly and without the extra cost of tooling changeovers.

A robust design as is always our hallmark.

Very rapid change.

Reduced investment for a single set of rollers, covering the entire range included in each Line model.

Very high automation level: minimum operator adjustment.

02

WELDING BENCHES

- Automatic

BELT ACCUMULATORS

- Horizontal

- Vertical

STACKERS / BUNDLERS

- Automatic

ELECTRONIC CUTTERS HSS/TCT